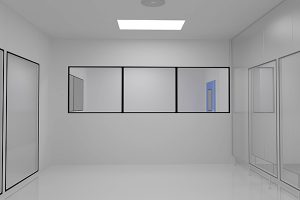

LexaMed assists pharmaceutical and medical device manufacturers by conducting in-vitro and in-situ disinfectant efficacy studies. Manufacturers must validate disinfectant regimens used in cleanrooms and other controlled areas to demonstrate efficacy of the disinfectants.

Disinfectant efficacy testing is conducted per several standards including AOAC Chapter 6 tests, ASTM E 2315, USP General Chapter 1072 and ASTM E 26140. Typical studies use coupons constructed of surface materials found in the facility. Coupons are inoculated with ATTC traceable organisms as well as environmental isolates unique to the client’s manufacturing facility. Application of the disinfectants to the coupons reflects the actual disinfectant application method used at the client facility. The effectiveness of disinfecting solutions against organisms within a manufacturing facility is becoming an increasing area of concern to both manufacturers and regulatory agencies. Below is a brief description of a disinfectant efficacy study.

In-vitro Study (in Suspension):

In-situ Study (with Surfaces):

If you would like to discuss your project with one of our experts, please fill out our contact form, and we will be with you immediately.

| Antimicrobial Agent | Materials (Testing with all agents) | Microorganisms | Time Challenges |

|---|---|---|---|

| Decon-Ahol (70% IPA) | Stainless Steel (316) | Pseudomonas aeruginosa | 5 / 10 / 15 minutes for all organisms, surfaces, and solutions |

| Hypo-Chlor (Chlorine) | Lexan (Clear Plexiglass) | Staphylococcus aureus | |

|

Vesphene® |

Wall (Epoxy Coated) | Candida albicans | |

| Decon-Spore (Peracetic Acid) | Delrin (Hard Plastic) | Aspergillus brasiliensis | |

| Steri-Perox | Nitrile (Gloves) | Bacillus subtilis | |

| Environmental Isolate #1, Bacillus sp. | |||

| Environmental Isolate # 2, Staphylococcus epidermidis |

Copyright @ 2023 LexaMed. All Rights Reserved